360kg Coffee Roaster: High-Capacity, Precision, and Consistency for Industrial-Scale Coffee Roasting

Time:

31 Dec,2025

In today’s rapidly expanding coffee market, consistency, efficiency, and flavor stability are critical for large-scale roasting operations. The 360kg coffee roaster is specifically designed to meet the demands of commercial roasteries, coffee factories, and large brand owners that require high output without compromising quality. As coffee consumption grows worldwide, producers face increasing pressure to deliver uniform flavor profiles, stable supply, and cost-effective production. The 360kg coffee roaster offers a professional, industrial-grade solution that bridges high-capacity roasting with precise control and reliable performance.

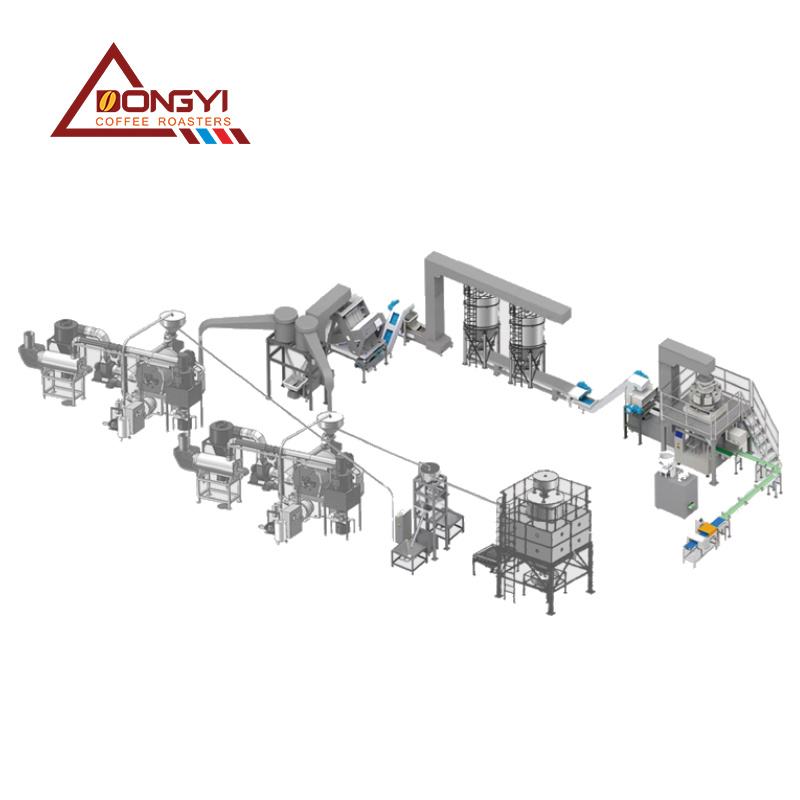

The overall framework of the 360kg coffee roaster is built around large-batch production, intelligent control, and durable construction. Its heavy-duty drum structure allows up to 360 kilograms of green coffee beans per batch, making it ideal for continuous production lines. The machine integrates advanced heat transfer technology, combining conduction, convection, and radiant heat to ensure even roasting across every bean. This balanced roasting mechanism prevents scorching, underdevelopment, or uneven color, even at maximum capacity.

One of the key advantages of the 360kg coffee roaster is its precise temperature control system. Equipped with high-accuracy sensors and an intelligent control panel, operators can monitor and adjust roasting curves in real time. This ensures repeatability from batch to batch, which is essential for maintaining consistent flavor profiles for branded coffee products. Whether roasting light, medium, or dark profiles, the system provides stable heat response and smooth transitions throughout the roasting process.

Efficiency is another major strength. The 360kg coffee roaster is designed for high thermal efficiency, reducing fuel consumption while maximizing output. Optimized airflow and insulation help retain heat within the drum, shortening roasting cycles and lowering operating costs. For large-scale producers, this translates into significant energy savings and improved profitability over long-term operation. At the same time, the robust cooling system rapidly reduces bean temperature after roasting, locking in aroma and preventing over-roasting.

Durability and reliability are central to the machine’s design. Manufactured with high-quality steel components and reinforced structures, the 360kg coffee roaster is built to withstand continuous, heavy-duty use. Key parts such as bearings, motors, burners, and control systems are selected for industrial performance, ensuring long service life and minimal downtime. This reliability is crucial for factories that operate on tight schedules and cannot afford unexpected production interruptions.

The role of the 360kg coffee roaster extends beyond simple roasting. It acts as a core production asset that supports brand consistency, supply chain stability, and scalability. For coffee brands expanding into new markets, the roaster provides the capacity needed to meet growing demand without sacrificing product quality. It also supports standardized production, making it easier to replicate signature flavors across different locations or markets.

In practical applications, the 360kg coffee roaster is widely used by large coffee roasting plants, export-oriented coffee manufacturers, and OEM suppliers for private-label brands. For example, a large coffee factory supplying multiple international brands faced challenges with inconsistent flavor and high energy costs using smaller, outdated roasting equipment. After upgrading to a 360kg coffee roaster, the factory significantly improved batch consistency, reduced roasting time, and lowered fuel consumption. Production capacity increased, delivery schedules stabilized, and customer complaints related to flavor variation were dramatically reduced.

From a customer pain-point perspective, the 360kg coffee roaster addresses several critical challenges. It solves the problem of inconsistent quality in large batches by delivering uniform heat distribution and precise control. It reduces operational costs through energy-efficient design and high output per batch. It minimizes labor intensity by integrating automated controls and stable operation, allowing fewer operators to manage higher production volumes. Most importantly, it helps coffee producers protect their brand reputation by ensuring every batch meets the same quality standards.

In addition, the 360kg coffee roaster offers flexibility for customization. Options such as different fuel types, advanced automation modules, data recording systems, and integration with factory production lines allow customers to tailor the equipment to their specific needs. This flexibility makes it suitable for both traditional coffee roasting businesses and modern, data-driven production environments.

In conclusion, the 360kg coffee roaster is a powerful, efficient, and reliable solution for industrial-scale coffee roasting. By combining large-capacity production with precise control, energy efficiency, and durable construction, it enables coffee producers to scale up operations while maintaining consistent flavor and quality. For companies seeking to improve productivity, reduce costs, and strengthen brand consistency, the 360kg coffee roaster is not just a machine, but a strategic investment in long-term growth and competitive advantage.

Recommended